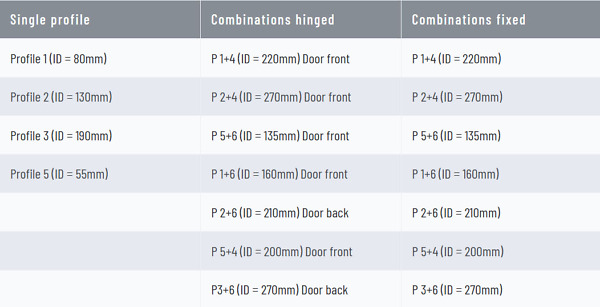

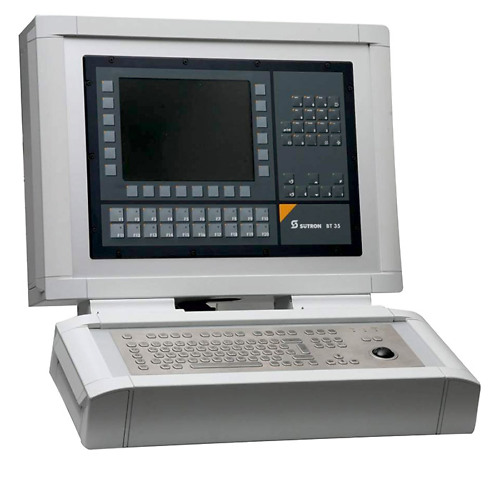

Profile combinations and installation depths

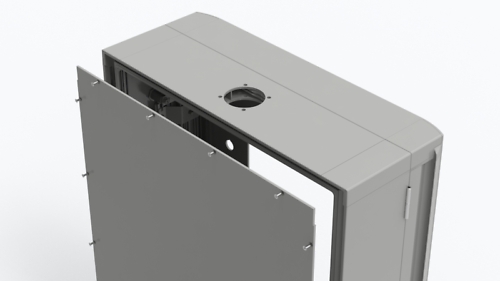

With 18 variants, the SL 4000 covers installation depths from 55 mm to 270 mm. The combinations can be hinged or fixed with screws. The rear panel can be hinged or screwed in place. The front frame concept of the operating enclosure allows controls from common manufacturers to be mounted directly via a mounting frame. Otherwise, the controls and operating units are mounted via a front panel.