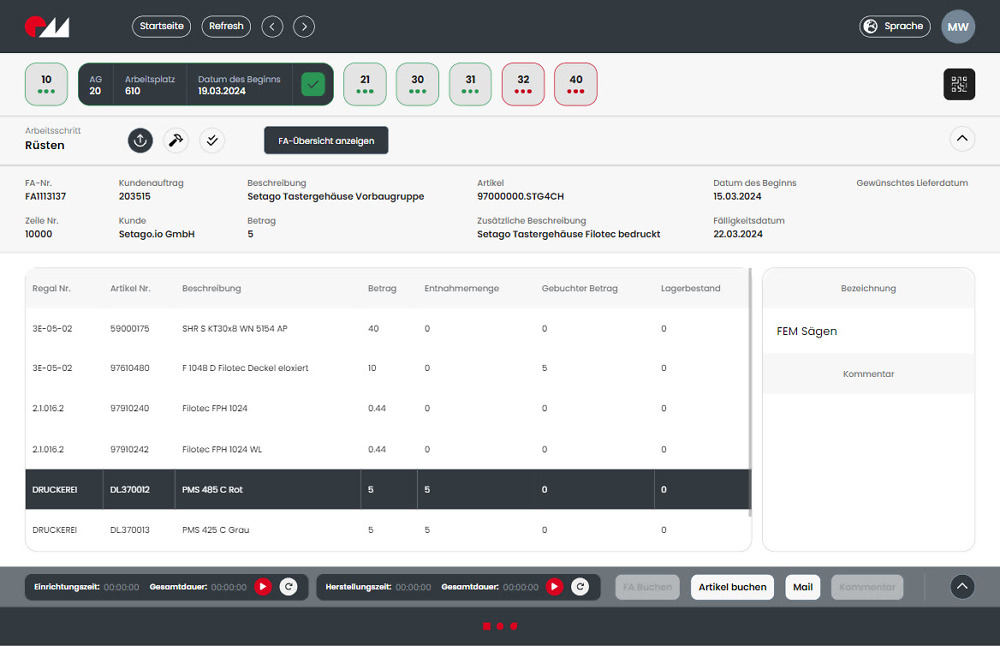

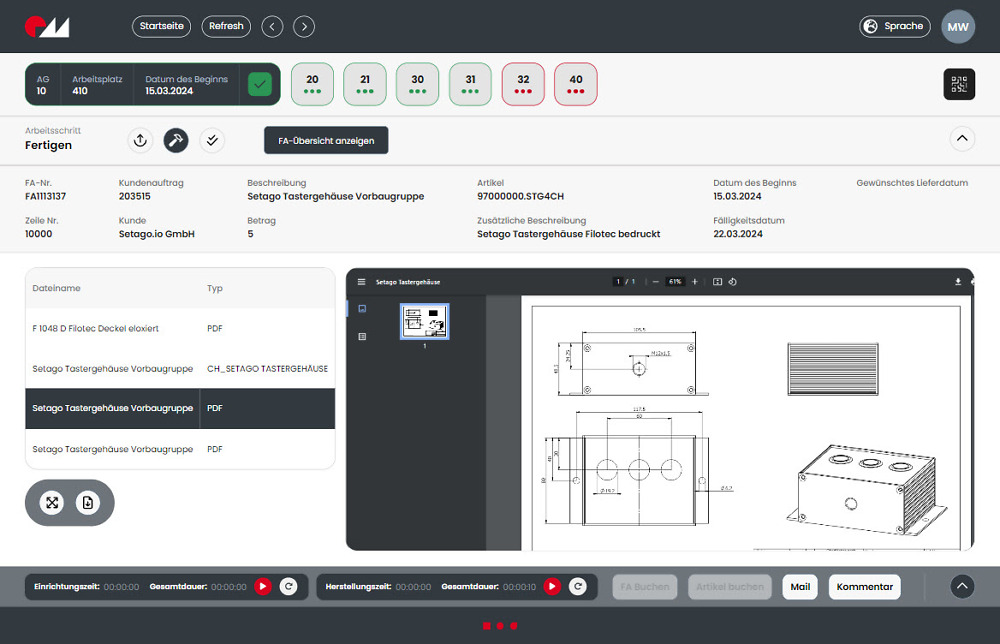

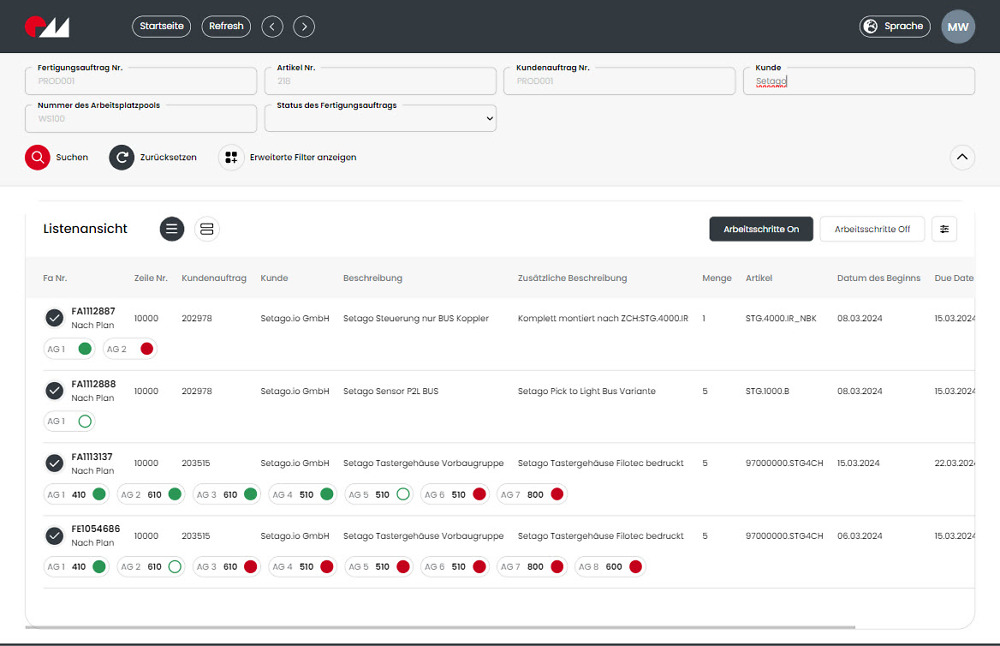

Order overview

All relevant information about the work orders, such as customer and article data as well as quantity and time data, are clearly displayed.

Filter function

Orders can be filtered using filters and search functions

Order information

In addition to the order numbers, customer, article, quantity and time details can be seen at a glance

Status of the individual work steps

Which job is at which workstation. If green, the workstation has already completed the job. Red shows the workstations that are still pending